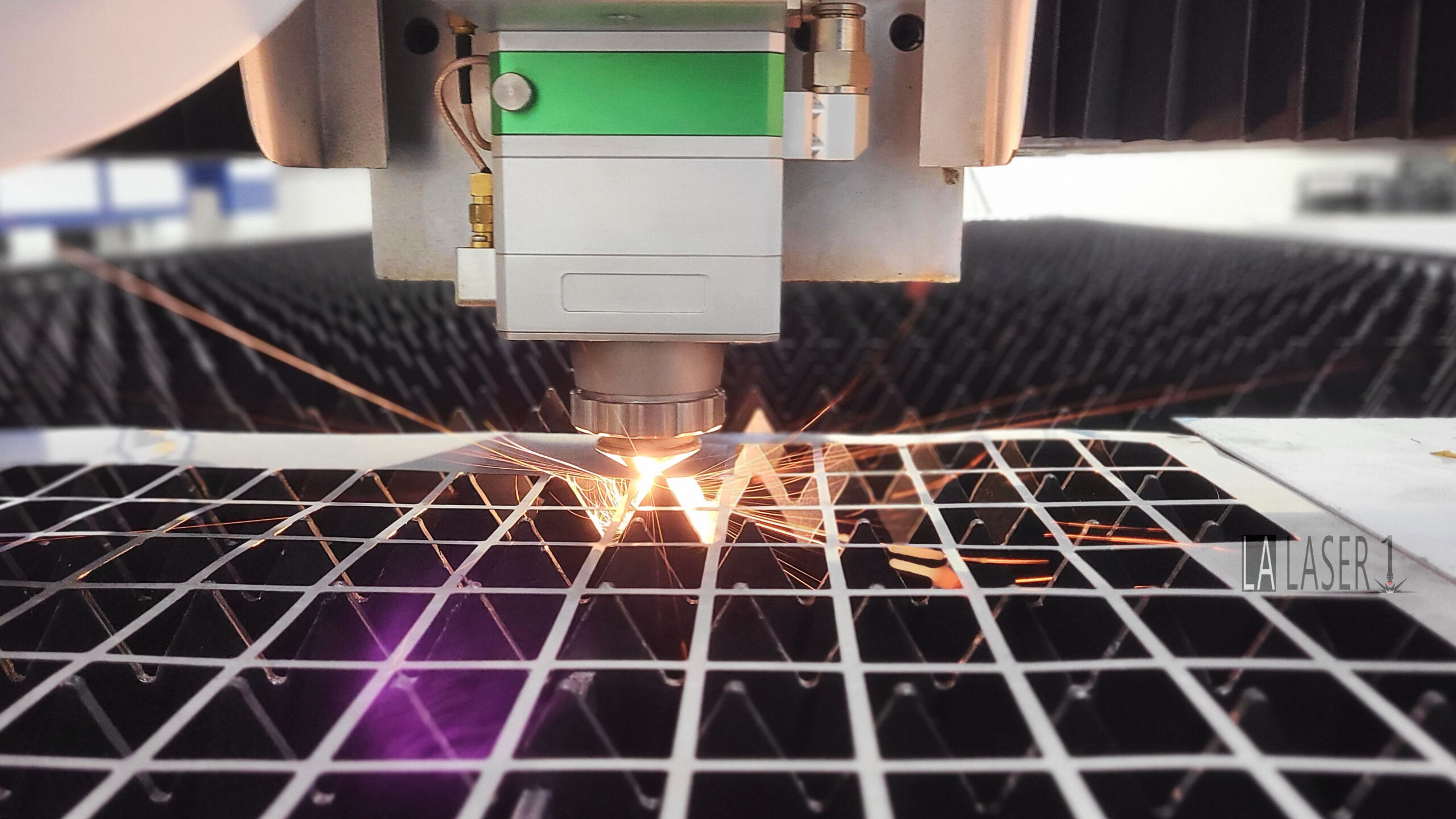

Laser Cutting Services in Valencia, CA

At LA LASER 1, we specialize in laser cutting services, providing you with precise and efficient solutions for a wide range of materials. Our state-of-the-art laser cutting technology allows us to achieve intricate and exact cuts on metals such as aluminum, stainless steel, and more. Whether you need custom shapes or detailed designs, our expert team ensures clean and accurate results every time. With laser cutting, we deliver precision that meets the highest industry standards.

——————————————————————————————–

Why Choose Our Laser Cutting Services?

- State-of-the-Art Equipment: We use the latest laser cutting machines for exceptional results.

- High Precision: Achieve tight tolerances and intricate designs.

- Fast Turnaround: Our efficient process ensures your project is completed on time.

- Custom Solutions: Tailored services to meet your specific project requirements.

- Eco-Friendly Process: Minimal material waste and efficient energy use.

Cutting Thickness

At LA Laser 1, we specialize in high-quality metal laser cutting services for various applications. We handle a wide range of metals, including:

—————————————————————

- Steel: Up to 0.78 inches (20 mm)

- Stainless Steel: Up to 0.47 inches (12 mm)

- Aluminum: Up to 0.35 inches (9 mm)

- Non-Ferrous Metals: Up to 0.27 inches (7 mm)

—————————————————————–

Supported Materials:

Spring Steel

Carbon Steel

Stainless Steel

Aluminum

Brass

Bronze

Copper

Titanium

Tool Steel

The measurement unit is millimeters (mm).

Applications of Laser Cutting

Our laser cutting services are perfect for industries such as:

- Aerospace: Precision cutting for complex components.

- Automotive: High-quality parts with tight tolerances.

- Architecture: Intricate metal designs for modern structures.

- Electronics: Small, detailed parts for advanced devices.

- Medical: Custom tools and components for medical devices.

———————————————————————————————————-

Advantages of Laser Cutting

- Unmatched Accuracy: Perfect for intricate designs and small components

- Smooth Edges: Minimal finishing required, saving time and costs.

- Versatility: Handles a wide range of materials and thicknesses.

- Cost-Efficient: Reduces material waste, making it a budget-friendly solution.

- No Tool Wear: Contactless cutting eliminates tool wear and reduces maintenance costs.

How Does Laser Cutting Work?

Laser cutting uses a concentrated laser beam to heat, melt, or vaporize material, creating precise cuts with minimal distortion. This technology enables faster production, improved quality, and consistent results. Learn more about the laser cutting process here.

Additional Resources

American Welding Society on Laser Cutting