Welding Services in Valencia, CA | LA LASER 1

Precision Welding for All Your Needs

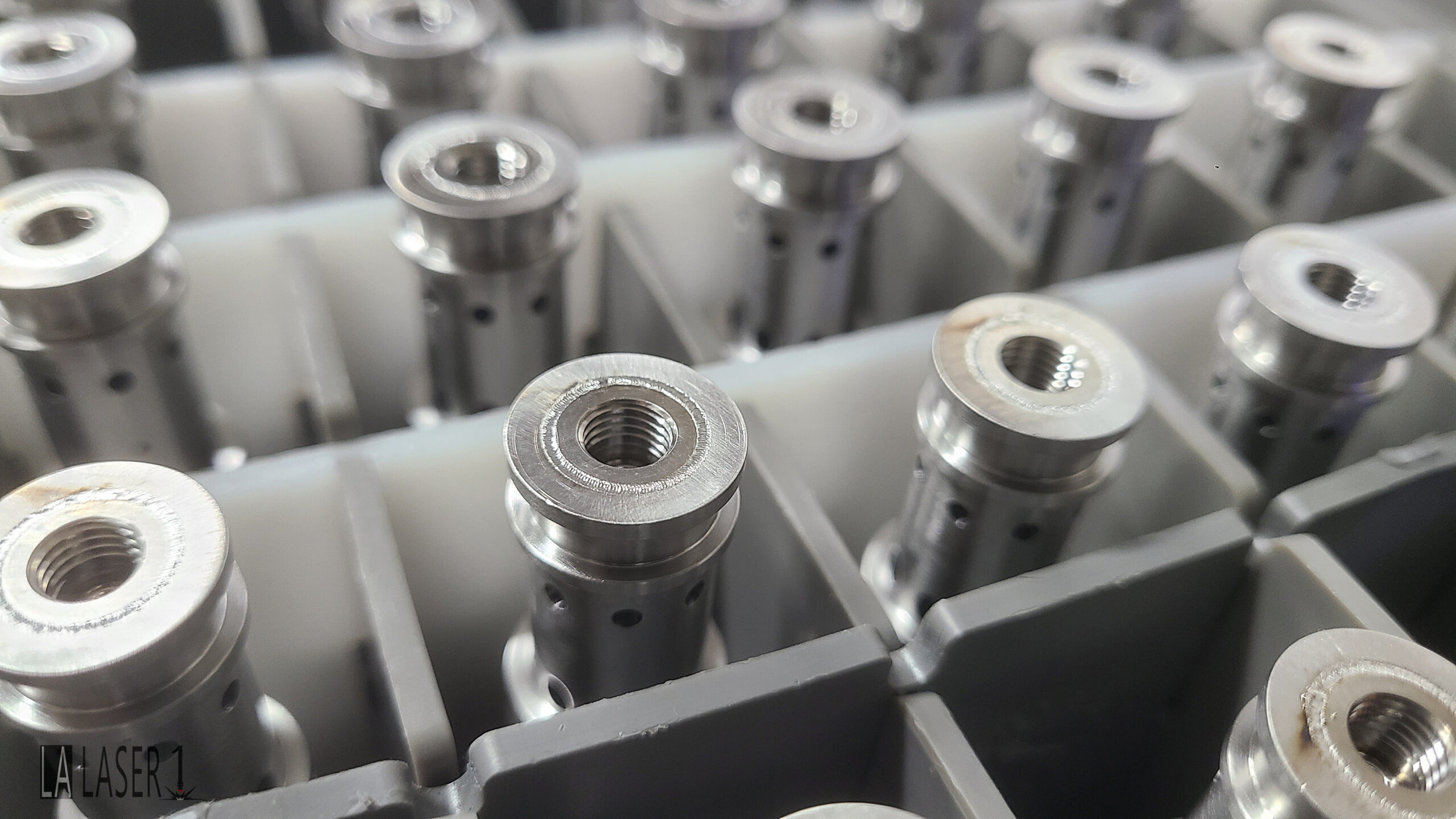

At LA LASER 1, we specialize in delivering high-quality welding services to meet your unique project requirements. From laser welding to TIG, MIG, and arc welding, we offer cutting-edge techniques tailored to industries like aerospace, automotive, medical devices, and electronics. Our expert team ensures precision, durability, and efficiency for every weld.

Laser Welding

Laser welding is a modern welding technique that utilizes a high-intensity laser beam to join materials together. Learn more about welding standards and techniques at the American Welding Society.

Applications of Laser Welding:

- Aerospace components

- Medical instruments

- Electronics assembly

- Automotive parts

Application Advantages of Laser Welding

Deep Weld Penetration

Weld penetration can be closely controlled and ranges from a minuscule 0.005 inches to a depth of up to 0.25 inches.

……………………………………………………………………………………………………………….

Micro Part Welding

Given the small and precise nature of the laser beam, very small and very thin materials can be easily joined. This includes welding of foils, stents, sensor diaphragms, and surgical instruments.

……………………………………………………………………………………………………………….

Low Heat

Pulsed lasers can minimize the amount of heat applied to a part, thus helping to keep critical electronics and other components cool.

………………………………………………………………………………………………………………..

Dissimilar and Crack Sensitive Material Welding

Laser welding can join dissimilar materials and also crack sensitive materials.

…………………………………………………………………………………………………………………

No Vacuum Requirement

Laser welding does not require the parts to be in a vacuum, which can result in faster production cycles.

………………………………………………………………………………………………………………..

High Feed Rates

Laser welding can occur at feed rates up to 200 inches per minute, which is much faster than conventional welding processes such as MIG and TIG. High feed rates mean faster welds and lower costs.

TIG Welding

TIG welding provides exceptional control and precision, making it the go-to choice for clean and strong welds on intricate designs and thin materials. Ideal for stainless steel, aluminum, and more, this method ensures durability and an impeccable finish.

For additional information on TIG welding specifications, see the AWS resource page.

MIG Welding

MIG welding offers versatility and efficiency, suitable for both thin and thick materials. Known for its speed and adaptability, it’s an excellent choice for aluminum and stainless steel applications.

MIG welding is known for its speed and versatility. Learn about MIG welding standards at the AWS MIG Welding guide.

Arc Welding

For heavy-duty welding needs, arc welding delivers unmatched strength and versatility. This technique is ideal for robust, long-lasting welds on a variety of materials, including aluminum and steel.

Why Choose LA LASER 1 for Your Welding Projects?

- State-of-the-Art Technology: Advanced tools and techniques ensure top-quality results.

- Experienced Team: Highly skilled welders with years of expertise.

- Fast Turnaround: High feed rates and efficient processes reduce production time.

- Custom Solutions: Tailored services to meet your specific needs.